The highest level of expertise in development, project planning and production is the basis for all our agitators.

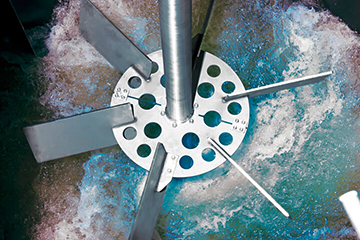

The design and use of a suitable impeller is not trivial. The design and construction, …

Mechanical seals are indispensable in agitator technology. MUT-Tschamber was one of the first companies to, …

The highest level of expertise in development, project planning and production is the basis for all our agitators.

The design and use of a suitable impeller is not trivial. The design and construction, …

Mechanical seals are indispensable in agitator technology. MUT-Tschamber was one of the first companies to …

WITH AN EYE ON THE ESSENTIALS

MUT-Tschamber is a technical leader in the development and servicing of sustainable agitators. We develop, design, build and maintain agitators, impellers and mechanical seals for our international customers. To achieve their ambitious goals, we use innovative technologies such as configurators and simulation models developed by us.

The Result: Sustainable Agitators.

APPLICATION AREAS

There is hardly any industry in which stirring technology is not used today. This is precisely why MUT-Tschamber is committed to not loosing sight of one thing – sustainable solutions. Because that is what matters in all industries: How sustainable are the agitator solutions, how energy and cost efficient?

APPLICATION AREAS

Range of services

Our more than 40 years of experience in designing, constructing and manufacturing of agitator technology – agitators, impellers, mechanical seals – forms the foundation for future-oriented products. With our focus on sustainability and virtual systems, we offer our customers more: competitive advantages in the production process.

SIGNIFICANT INNOVATIONS

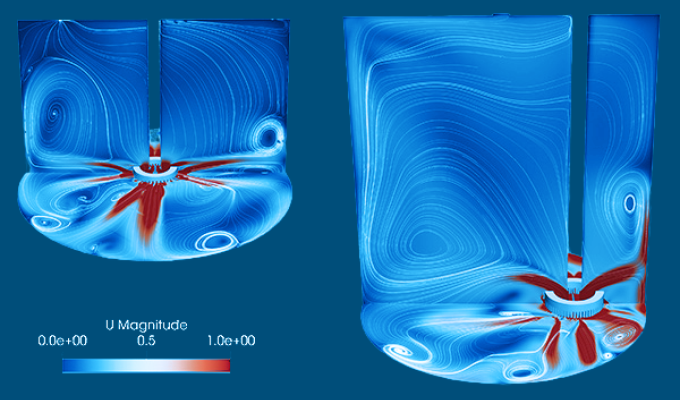

MUT-Tschamber has access to a specially developed CFD simulation tool. The flow simulation, Computational Fluid Dynamics (CFD), enables us to analyze the movement of fluids within an agitated system, including the interactions between the fluids and the agitating elements. This leads to a deep understanding of the process, which in leads to results in the optimization of the design of agitators, the possibility of scaling processes and significant cost efficiency.

ENERGY EFFICIENCY FIRST AND FOREMOST

SUSTAINABILITY AT A GLANCE

Agitator technology plays a central role in many industrial processes in which mixing, dispersing and homogenization tasks have to be performed. Agitators typically consist of a motor, a drive shaft and an agitating element. The agitator elements are used depending on the requirements and viscosity of the medium. Process technology designed precisely for the stirring task shortens reaction times and improves product quality.

Sensors and measuring devices help to monitor and optimize process parameters such as temperature, viscosity and stirring speed in real time.

Sensors and measuring devices help to monitor and optimize process parameters such as temperature, viscosity and stirring speed in real time.

One of the biggest challenges in agitator technology is adapting it to the specific requirements of the respective process. This includes selecting the appropriate agitator and optimizing the agitator speed. Using CFD (Computational Fluid Dynamics) simulations and other advanced analysis methods such as Condition Monitoring, MUT-Tschamber is able to model and optimize the agitation process to achieve maximum efficiency: sustainable agitators.

In order to provide you with an optimal experience, we use technologies such as cookies to store and/or access device information. If you consent to these technologies, we may process data such as browsing behavior or unique IDs on this website. If you do not give or withdraw your consent, certain features and functions may be impaired.